$99 DIY Filament Making Machine - Make Your own Filament at Home

Комментарии:

very good idea

Ответить

Bro did you used a "drill bit " as a screw feeder

Ответить

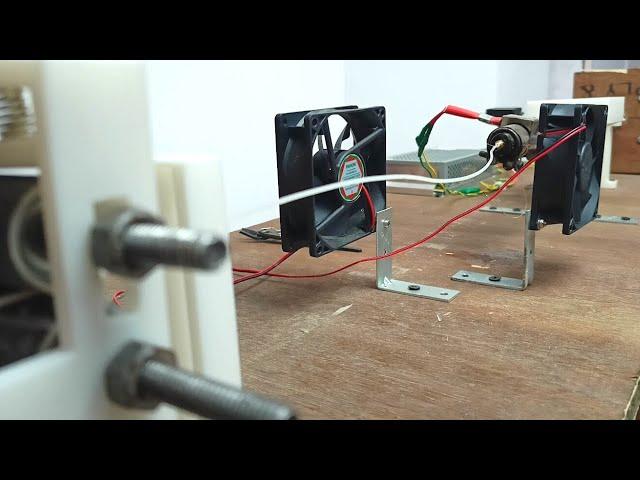

Great machine, and wow, you have phenomenal prices! The two 12v pc fan for $2, that"s unbelievable! The word very in prices is an understatement!!!

Ответить

Yeah bro can u help me to do the final year project

Ответить

Am i blind? Do you have a list of the parts? I see the link for the 3D parts, but if im going to the hardware store, i need a list

Ответить

Hi can you explain on how your heater actually working? I'm a bit lost at that part...

Ответить

Nice job for a simple approach. Feedback loop for the puller for the win.

Ответить

can you replace the DC motor with something like a wiper motor for the auger motor?

Ответить

Thankyou for making this video in detail❤

Ответить

Where does the source material come from, the little plastic beads?

Ответить

Successful! Is that an Indian remake of George Michael’s Careless Whisper? 😝

Ответить

With a few tweeks, i can see the automation of the RPM for a consistent diameter! Well done!!

Ответить

Could you make pellets out of a water bottle so that you could make big spools

Ответить

Can you try and make one using parts from a ender 3 printer ?

Ответить

Hello dear friend, I ask you to write to me what settings you made in the ''cura'' program to print What settings did you make I just can’t find the settings for this , so that the 3D printer prints well Thank you in advance I really liked the video and I wrote you a like

Ответить

What i really want is machine to turn all these PET bottles into filament

Ответить

You made what people made for a lot more money, just without a shredder and eithout a feedback loop

Great idea with the drill bit :)

Pure Definition Of Hardwork

Helped me a lot

The cost helped me to save and buy other parts

thanks dude !!

The first thing that comes to mind is using a feedback loop that is able to measure the width of the extruded plastic and adjust the roller speed accordingly

Ответить

Would it be better to have a half pipe setup at the end of the extruder so the filament doesn't stretch or sag as it passes along to the end onto the spool? I ask because I am getting an ender 3v2 in a couple of days (my first adventure into 3D printing) and I want to try make something like this so I can try and become as self sufficient as possible.

Ответить

screw press through filament nozzle directly into filament or from plastic beads direct to a printer, yes a filament extruder on a 3d printer accessory

Ответить

Perfect job

what kind of material used in pla filament can you tell me the grade numbers?

Nice work

Ответить

Can you make video or attach links to everything you bought and where go get it. Even the machine shop diameters

Ответить

this is great man, i really want to see home filament extrusion become more common, its great to see u put in work on this

Ответить

who saw the spider ?

Ответить

Таким ужасным инструментом мерить пруток, категорически запрещается!!!!!!!!!!! У тебя погрешность будет огромная а ты даже знать не будешь какого диаметра пруток давится!

Ответить

This is amazing! Can you try running some recycled bottle material through it and make a vid on that ?

Ответить

Hei my friend. Could you help me with the drill size and bearing sizes that you used please? Did you need to rework the drill to fit in the role of bearing?

Ответить

I'd love to turn all the car bumpers that I see on the side of the freeway into filament. As I understand it, they're made of polycarbonate. Maybe someday a laser micrometer will be priced low enough that it can measure the filament at the nozzle as it's extruded so the puller can adjust the speed for a perfect dimension.

Ответить

That's really cool !

I'm considering building my own filament machine and your video is really great to see all the components needed.

Wow, cool build! and the benchy turned out amazing all things considered!

Ответить

You need to allow the filament being pulled out to drape down into a catenary before being rolled up. This affects the average diameter of the filament being extruded.

Ответить

Great job! I love your passion you working with💪🏻

Ответить

Very nice project! Absolutely good information with the specifications of each of the components. I'm looking to build a simple extruder too. This will be very good reference to find the components.

Ответить

very smart design! i hate how expensive filament is, considering how old and simple the process is. also, you are quite handsome X3

Ответить

Wow!!!! Love ur idea!!! Do u have parts list for it??? Would love to make one my self.

Ответить

Incredible work, I will definitely be referencing your project when I get the space to do some filament recycling. Turning supports, brims, failed prints, and measurement tests back into usable filament is my dream. 50/50 virgin/recycled material would be a good enough win, but I think I might tolerate some "bad" quality if it could be 80 to 100% recycled plastic.

How's the cost of virgin pellets per kilo versus filament? Are you stuck buying larger minimum quantities?

Awesome Job !

I would definitely make my own DIY filament extrusion machine !

Good Luck Mate!