Комментарии:

First 🙃

Ответить

great video! any idea when defiant welding gloves will be back in stock?

Ответить

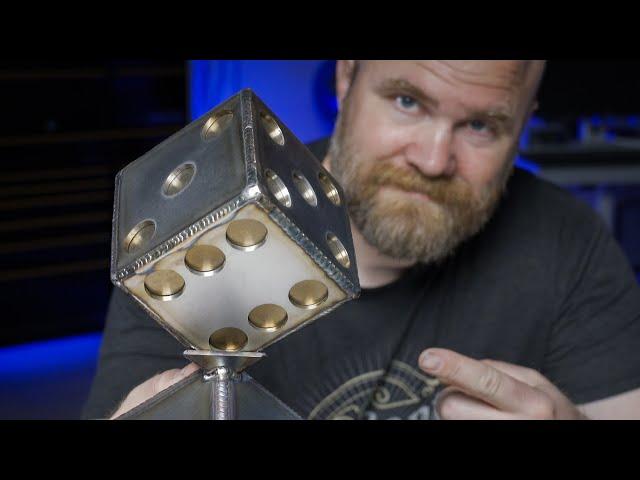

Love This Sculpture

Ответить

Great vedio when will the DXF files be available or are you going to offer drawing with dimensions

Ответить

Cool video, great job!

Ответить

Wow that's crazy awesome. Keep up the great craftsmanship and hard work my friend. Keep welding. Keep making. God bless.

Ответить

Seems like you came up with this project just to get the sponsor off your back or to get the initial sponsorship either way sponsor video

Ответить

November last year, I took my collection of stainless to a friend's and cut concentric hexagons out of it.

The plasmacutter did horrible things to the stainless. Foamy, sharp, black, and horribly hard.

It took me 60 hours over a couple months to clean the dross and slag from the 6 inside walls, 6 outside walls, top, bottom, and the 24 slaggy edges from 160 hexagons. It was so horrible that 90% of that now clean stainless is still sitting in the 5 gallon bucket in the garage. I have another 160 pieces of stainless that if I cut into the same sizes of hexagons, would be ... 160x5 800 hexagons to sand, makes me just want to quit and do something completely different. What can I do to make the plasmacutter not absolutely butcher the stainless?

Additional note, if anyone wants to build a buckyball out of 20 same sized hexagons, be sure to first build a jig to place the edges together at 138 degrees with a gap in the middle of the jig for the weld. Be especially particular that any 2 pieces come together at the same angle while looking at the faces, and geez, how to say, the edges come together evenly and not at the slightest of lap weld. Or thou shalt cuss.

Justin,

Your Powermax 85 is capable of using nitrogen as a cutting gas. Using nitrogen will greatly reduce/eliminate the nasty edge quality and dross that compressed air leaves behind. Cut speed and arc voltage are almost identical to what is provided in the Hypertherm manual. Nitrogen also does and excellent job on aluminum.

That is sweet thank you for sharing

Ответить

This was surprisingly inspiring justin! Good to see you again bud, keep it up!.....d*mn! You didn't have a CNC table that long ago, NICE upgrade. Been wondering if that investment($4000-$6000) would be worth it for me tho. Prolly take several years to see a R.O.I. on it tho.

Ответить

Sensacional!!!👏👏👏👏👏

Ответить

YOU ~ ROCK ! ! Chicagooooooo

Ответить

I want to try this only with plug brazing the holes with silicon bronze and grinding flat. Nice video man!

Ответить

I saw this guy in doc stream so I came to see who he is

Ответить

❤️👍💕💐

Ответить

Did you let it cool down before welding each side?

Ответить

No kits available at the link…

Ответить

Where is the DXF? Thanks, great video!

Ответить

GrandiosoooOoo😍💥

Ответить

110A was what you settled with? Yeah, sounds right, cool! Stainless way cooler welds than steel.

Ответить

Looks great, I feel you might want to figure out how to get arc shots viewers can see

Ответить

Started with no gloves. Then one glove. When things got hot two gloves. PPE rulzzzz

Ответить

Hey who makes the blue and gold back cap you had on there

Ответить

Boop

Ответить

Great work! Are kits still available?

Ответить

d

Ответить

Turn your heat down to around 90 amps. Also turn that gas flow down. Weld S.S. as absolutely cold as you can. Only enough heat to feed the wire on an even flow.

Ответить

That's so cool. I'd love to have a go at making one of those. After having seen this I'd order the kit from you straight away, but alas I'm in England and shipping would be so expensive! Perhaps I may have a go at downloading the plans, but I'm not sure how I'd cut the parts out , as only have basic tools. Thanks for the video, enjoyed watching.

Ответить

![Как казаки... - (все серии) [1967-1995] Как казаки... - (все серии) [1967-1995]](https://ruvideo.cc/img/upload/ODFRQWhRYmxVMFc.jpg)