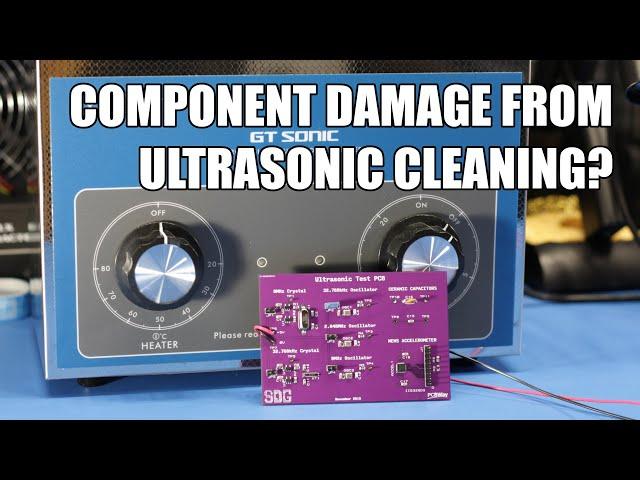

SDG #118 Can ultrasonic cleaners damage your PCB and components?

Комментарии:

There is no such thing as free PCB, the cost was putting your local PCB fab out of business.

Ответить

MEMS may be destroyed

Ответить

Very useful Video Steve,I've always wondered about the effects the ultrasonics would have, I have more confidence in using mine now👍👍

Ответить

is this a sweeping frequency cleaner or one for cleaning jewelry that stays at 40hz?🤔

Ответить

What about MSL 3 components that absorb moisture from the air?

Ответить

Modern IMUs that I have seen have a high max acceleration (in terms of damage, not measuring). The MPU9250 has a max rating of 10000g for 0.2 ms when unpowered (I have no idea about powered), since it is such a small and light device getting it to 10000g is probably pretty difficult in the first place and the frequency of an ultrasonic cleaner is that high that for 45 kHz the period is 0.02 ms so a tenth of that the rated time too and even within that the max acceleration will be for a much shorter period of time.

It would be interesting to measure the acceleration using an accelerometer whilst it is in the cleaner. A +-16 g one might not be enough but you can quite easily get +- 200 g ones for model rockets and similar applications. You should probably add a conformal coating first though, preferably a hard one so it doesn’t dampen the vibrations.

Face -> Palm. Learn how to: test. Learn how to: draw schematics. Truth may hurt, but this video is bloody awful and I make no apologies for saying that.

Ответить

I realize this is a 2 year old video. After a run of boards came back with a high percentage of failed IMU's, I conducted an experiment on my bench. I took a board with a working IMU and placed it in distilled water inside my Branson 2200 ultrasonic cleaner for 10 minutes. After drying the board, I retried the firmware and the IMU was now returning 0's for Gyro reads on all 3 axis, and extremely erroneous Accel results on all 3 axis. This is with a TDK Invensense part. So while I'm sure there are some parts that are unaffected, people should probably refer to appnotes from the manufacturer.

Ответить

Such low frequency loss is likely to be the ambient temperature rather then effects of cleaning.

Ответить

People wash $2000 video cards in ultrasonic after repair is done.

Because it's not harming anything. Even the cristal.

Ever since I demonstrated that my ultrasonic cleaner could put pinholes in aluminum foil, I have been worried about damaging things.

For example, I've destroyed print heads with a conventional ultrasonic cleaner. But I did read somewhere to to clean print heads, you have to use frequencies around 80-90 kHz. I don't know where you buy those.

Also the ability of the UC to get into cracks and the smallest of features makes me wonder if it could follow the legs into chips .

how come when I dropped my phone in the bath it didn't work even after I dried it with my hairdryer yet you can put your stuff in that bath and it works?

Ответить

Can you explain what the Earth's magentic field has got to do with an accelerometer?

Ответить

How would a power supply hold up? Can you ultrasonic clean those? Trying to think whether any materials are in those that aren't in a typical pcb/mobo etc.

Ответить

what liquid do you use for pcb cleaning?

Ответить

I used PCBWay once. The circuit board was slightly over 100 x 100mm. It ended up costing me €80. The exact same circuit (same Gerber files) from JLCPCB cost me €10. So no way pcb way.

Ответить

Another thing to consider is that the liquid could seep into your plastic packages of your ICs. It might short out pins, which in turn could carbonize the substrate and create shorts. Also if the part gets hot, the liquid might boil and blow your packages apart.

Ответить

I am a beginner - which software did you use ?

Ответить

This is nice and I appreciate the effort you put into it. That said is an n=1 meaningful here? I mean isn't ultrasonic cleaning the sort of thing we expect to raise the odds of failure not just outright cause it? I have seen it fracture bond wires.

Ответить

First hand experience: Piezo buzzers (in this case small SMD buzzers) generated voltages from the ultrasonic excitation. The micro on the PCB had some pins fried because of it. This was during a first production run, so in this case the solution was to use a different cleaning method, but the point is it can certainly cause problems.

Ответить

How did you do with import duties with PCB Way?.. I got some PCBs from them and ended up having to pay nearly their value again in customs duties.

Ответить

I've got a component here keeps waving it's fist and shouting "these ultrasonic cleaners, their houses are filthy.... and they've got stupid high-pitched squeaky voices.... why don't they go back to where they came from?". I said to it, "You're so intolerant to ultrasonic cleaning!" I'll get me coat.

Ответить

Not sure why would you test "earth's magnetic field" with accelerometer that's not the part that gets damaged. It is usually the MEMS part and after that earth gravitational field either does not have effect on accelerometer or it does not work at all. I've damaged complete batch of prototype boards for customer and after that I never put boards with accelerometers in ultrasonic. The rest is fine i never noticed any damage on the crystals at all.

Ответить

“2 hours seems a little excessive” - I once left an iPhone 7 PCB in the bath for 2 days by accident - still worked 😂

Ответить

Thanks for sharing all this!

Evidently the modern components are quite tolerant to ultrasonic. I still remain unsure about old TO-5 packaged transistors like 2N1613, 2N7011, 2N2905 or even the TO-18 types which also have bonding wires hanging supported only by their welds at the ends. Then another message here also reminded about the kovar leads going through the glass into the interior. Some lead length above the board might produce a detrimental resonance at the ultrasonic frequency?

Come to think of it, I have both several of those old metal can parts, a small ultrasonic cleaner and means of determining the frequency and maybe the resonance frequencies (in air). So maybe I should take the matter into my own hands an perform a few tests...

Marvellous! Another uncommon test that clarifies the ultrasound damage debate. Well planned, well presented, well scripted. THANKS!

Ответить

🎵Good Vibrations🎵 👍😁

Ответить

Elmasonic has P Series ultrasonic cleaners that can sweep at 80kHz which is gentler and safer for more sensitive components than the usual 37-40kHz. Curious how that would fare in comparison.

Ответить

Oh good, another shill for PCBway. Moving on...

Ответить

Thank you for sharing this video , really informative

Ответить

Which solder paste are you using? Yellow Solder Paste is wrong in description, sorry. lol. You miswrote, should be renamed to solder flux

Ответить

Another concern more so is damage to components at the components physical connection point (end caps of capacitors / resistors) & soldering joint integrity of improper setup / type / power level of ultrasonic uses.

Ответить

Those numbers are probably within the component tolerances. You didn't exactly tell us what were the tolerances of the parts used, but I don't think you used anything extremely accurate or high tolerance but something quite common?

Ответить

That is Impressive! A great pleasure to work with you, Steve!

Ответить

I haven't had issues with the ultrasonic damaging components so far but I have had issues with flux migrating during the cleaning and turning into a thin film on contacts and that causing issues until manually cleaning.

Ответить

Great testing. It looks like the 8MHz oscillator at 9Hz change is about 1ppm which is nothing.

Ответить

Hi Steve, recently found your channel very impressive. Anyway, one of your videos implied that you had ordered parts from LCSC. How did you find them? Where they 'Chinesium' or of quality and genuine?

Thanks Bud

The frequency measurements of the crystals are meaningless unless you control for temperature. The delta that you see could easily be explained by temperature differences.

Ответить

To be honest 2 times i fixed some HMI panels (siemens) after washing these in the ultrasonic cleaner didnt works no more,then i analyzed the boards i seen some mosfet and inductors was ko i dont know how it is been possibile but this is what happened!

Ответить

It should also be mentioned, that not all SMD LEDs are tolerant of ultrasonic cleaning, like the Cree UHD1110 series. So taking a look at the datasheet beforehand is probably a good idea :-)

Ответить

Way back in 1972 when I left tech I got a job with a watch maker, as the newbie I got the job of taking clocks apart and cleaning them.On this occasion I put the parts of an alarm clock and a grandfather clock into the ultrasonic cleaner just before I went to lunch, when I got back some of the alarm clock parts were no longer and the grandfather clock gears had holes in them, the cleaning solution used was toluene, the cavitation was what did the damage brass parts.

Ответить

Did you check the ambient temperature during the measurements?

Ответить

Another great video! As an aside, testing for vibration and shock are frequently lumped together in a common specification, and for crystals, the shock specification is usually much more problematic. So I would be more worried about dropping the board on the floor (yes, I am very clumsy) than putting it through the ultrasonic cleaner! ;-)

Another note. The PCBWAY 5th year badge is very catchy, but it looks way too much like a stylized SS insignia to me. I guess this just isn't a thing in China, but I can't imagine any western company letting this logo out...

Anyone have experience trying to ultrasonic clean an ESP32 or similar?

Ответить

There are a few extra mistakes in your data :

- for the 32.768MHz XTAL the 1->2 difference is 70mHz not 1Hz

- the "before" number you wrote for the 32.768MHz XTAL is probably wrong as it doesn't have the same number of digits as the rest

- for the 2.048MHz Oscillator the 1->2 difference is 860mHz not 868mHz

Is putting electronics in water ever a good idea?

Ответить

Good job Steve 👍 Think I've only ever had problems with switches after being in the ultrasonic, and even then after they've cooled and dried most have still worked again.

Cheers

John

Now i understand why i've lost a compass on my iphone 6 :D ups

Thanks for clarifying this

Hi, have watched a few of your videos and just subscribed! What is the backend of the air gun you used to blow off the board? Is it a regular compressor or an air can? If the former can you share the details of the unit ? Thanks!

Ответить