Upgrading a CNC machine never ends

Комментарии:

Hi Bryan You are wrong about one thing .......... the upgrades to your machine will stop after you DIE ha ha and yes I also have a list of upgrade to do in the future, I run a C5 1605 screw on my Z and glad I went that size. Yeh I have found my MQL system to work really well with alloy so it will be good for you to have both flood and MQL any way keep at it Cheers Bill

Ответить

Love watching your build progress over time, and how you can so easily say - I'll do ...... in Python - as if its the easiest thing in the world, it's NOT for the rest of us :)

Aligning a rail to another rail helps - but is the reference rail straight?

To do this there needs to be a machined surface to butt the "first" rail up to, so it is located. The second rail can then be aligned to a known qty.

Without really significant work reworking your tubes, maybe on your next big change, you already have everything you need.

Use the laser alignment on the rail to check the straightness of the reference rail.

The laser does NOT have to be parallel and all the "fun" that involves. Just find the difference one end to the other and check the intermediate points are where they should be.

While I feel your pain with the plug removal without doing this all you may have done is reduced head nod (important) but not improved straightness (vital).

For a build that is rock solid (granite) have a look at PiotrFoxWysocki videos.

No special tooling, no special knowledge just dedication and time.

He builds an AWESOME machine and if you are after flood cooling for aluminum (or anything else) - his is SUPER Awesome

Cool upgrades Bryan 💥

Ответить

Its worth the time to get the cross beam right.

Now that you have a working machine, consider ordering a beefier cross beam, machine each face flat, mill a slot with the mounting holes, maybe give the rail a few thou for very slight adjustment, but I think not making that bottom rail straight / square will always give you some issues.

MQL is 100% worth it. I'd go with 2 nozzles if you can.

Ответить

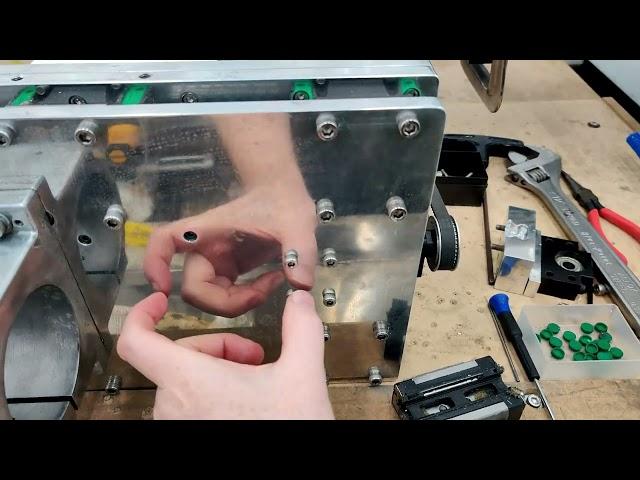

I love watching the upgrades on your machine, it has completely changed from the original Printnc.

On your double ballnut you can adjust the preload using the 4 grub screws in the middle piece, they act on the second nut to turn it slightly to increase or decrease the preload.