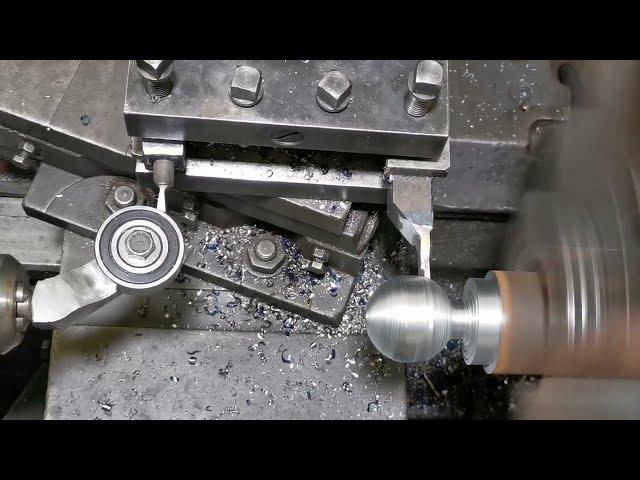

Making a Lathe Ball Turning Tool | Tie rod ball pin size reapering tool for lathe machine

Комментарии:

👍🏼👍🏼👍🏼👍🏼👍🏼❤❤

Ответить

А другую сторону как всё-таки делал?😂Тоже напильником на глаз?Так это не есть хорошо.

Ответить

Brilliant!👍👍

Ответить

Atencion : Tenes un calibre de buena calidad ,quidalo. La marca BORLETTI esta` fabricado en ITALY ,esta` fabrica hacen los instrumentos de medicion para la FERRARI y otras industrias. .Por experiencia de Tornero te aconsejo ,poner una punta redonda en el copiador tocando el rodamiento.

La herramienta de corte tambi`en si tiene punta redonda de 1/8' radio. Te deja la terminaci`on ma`s pulida y sin lineas or sept en la bola.

Un Saludo desde CANADA.

Just found your channel and Subscribed. Nice work.

Ответить

Thats really a great Idea, its also quite simple and easy to set up.

I shall try making one.

Thanks.

С резцами напряг?Всю обработку точить отрезным резцом!

Ответить

Very good technique good to see

Ответить

Cool !

Ответить

Any number of bearings can be used please

Ответить

Brilliant.

Ответить

なるほど、最初は倣い旋盤かなと思ったのでですが、目から鱗でした。

貴重な情報ありがとうございます。

Excelente ideia,se a ferramenta do desbaste for com raio no corte ficará com um acabamento melhor ainda!!!

Ответить

too cool, my friend

Ответить

হেেময়েত। মুললল্লা

গান

Nice tune and video

Ответить

Nice. The other style is tough to use

Ответить

.μπράβο.

Ответить

Con courage ❤

Ответить

👏🏻👏🏻👏🏻👏🏻👏🏻

Ответить

❤

Ответить

Bravo ve abonelik

Ответить

Great idea

Ответить

Great idea❤

Ответить

KISS! This is a great idea. One thing that 😊may not be obvious to a beginner is that the follower has to be the same shape and size as the cutting bit.

Ответить

Bhaaji apne Val di side bhi dikhao compound slide aur carriage kis tarah chalne eh bhi dikhao

Ответить

Is it important bearing ring assemble angular size ? If we assemble the bearing in axis tail stock, did we this spherical ?

Ответить

Хрень полная

Ответить

Esférico?

Ответить

Nice and simple.... Great idea

Ответить

Good idea ❤

Ответить

This is Manual copy turning method....

Ответить

Falo me🎉🎉🎉

Ответить

Jste lepší než Einstein 👍🏆

Ответить

Very good, excellent video, congratulations.

Ответить

Excelente amigo, sigue adelante

Ответить

muy bueno por ser productivo te felicito por enseñar a los torneros una nueva y buena manera de hacer esfera con un copiador en el torno

Ответить

thanks alot brother🎉🎉🎉🎉

Ответить

Good yar❤❤

Ответить

Nice work

Ответить

Super, I like it 👌

Ответить

Perfeito parabéns.

As vezes preciso fazer esfera em em eixo mais faço usando os dois eixos.

Esse rolamento que vc usa como copiador tem um ângulo exato pra ficar?

Observei que carro transversal fica em ângulo também vc anda com ambos ou somente com um?

Se possível me passa esse projeto?

Great idea. Not copy milling it's copy lathe machine nice work

Ответить

Great idea and it seem easy to both make and use. Thanks!

Ответить

Eso es lo que me encanta ver técnicos que tengan coco de verdad bárbaro

Ответить

Господе Святый !глазам не верю я вижу нормально заправленный отрезной ,это старая токарная фишка радиус точить👍🫡

Ответить

One minute in & already the music is so annoying that it forces me to mute. I hope that I didn't miss any commentary.

Nevertheless, it is a very interesting idea. Not limited to making balls, I think. If there was a pattern held where the ball bearing is, it would follow that pattern. As long as it was not too long ... with no tailstock center, you would be limited by stick out.

Oop ... I didn't see Bruce Matthews comment before posting. He beat me to it.

I'm going to borrow your concept and expand it to accept longer templates to turn longer shapes using a template. But the idea of mounting the template to the tail stock and using the four way tool post as the holder for the cutter and tracer is all from you. THANKS ! ! !

Ответить