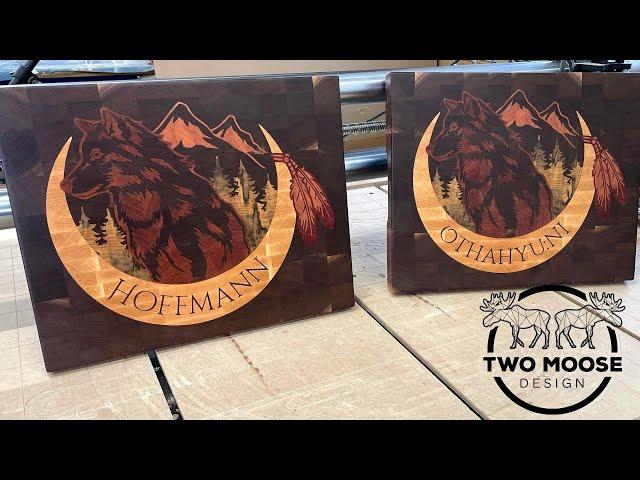

Building a End grain cutting board and adding Inlays

Комментарии:

Thanks for watching everyone 🙌🏼

Ответить

I having problems with my setting on this exact bit, can you help me!

Ответить

Great video. Thank you for sharing. A CNC related question. When you use the tapered ball nose bit does it not taper the sides and enlarge the opening as you go in deeper ? Also I would love to see more cnc inlay content. Thanks

Ответить

I want to learn more

Ответить

Did you design the vector files yourself?

Ответить

Great work helpful video, hat font did you use I have trouble inlaying font due to it will not go deep enough.

Ответить

assuming mistakes and not being ashamed, not only helps those who have the same type of activity, but also demonstrates moral integrity... CONGRATULATIONS

Ответить

Thanks for video, really enjoyed it, especially like the fact that you list links to all the bits and tools you used. Looking forward to more of your videos in the future

Ответить

Why didn't you do all the carving on the walnut board at the same time so there was no shifting? Thanks!

Ответить

What a beautiful way to honor the memory of your grandfather!! These are a meaningful and priceless gift for your mother and uncle. Epic result!!

Ответить

Thanks, would love to learn how to make inlays, do you have any videos show settings. Thank you again

Ответить

I too really really want to learn how to do these.

I make boards for family and friends as gifts. But this inlay scares me as i am afraid of the inlay failing.

Help would be great! Lessons learned and cutting depth and bit choice is needed. Ill never be in competition with the pros, but family and friends will be impressed 😁😁

Please make a video and spec sheet as needed.

Thanks

Doug

those boards are beautiful! great job.

Ответить

Beautiful!

Ответить

Please add more CNC inlay work. Thank you

Ответить

Yes I like more videos please 🙏🏻 how to video

Ответить

so....i fond u a few days ago. i been thinking none stop about wood. i have a few CNC tables that i been doing metal on. but just life now i have the cnc tables but no place to cut metal. but i have a large old 120year old barn that was passed on to me and my wife in the last 6 mouths. so i have been looking what to do with this cnc sutff and man i love watching you CH u have gave me a new idea with this wood stuf!!!! lol love it !

Ответить

Awesome job! Broinwood would be proud…

Ответить

Just found your channel. Great work. Only one thing I would question though.... Who would ever

use these works of art as a cutting board? Hope to see more.

Cheers

Great video. Did you use Easel on this project?

Ответить

Dude, how many hours did you put into these boards. Larry

Ответить

Yeah excellent job. I am very interested in learning more about inlay creation, Thanks

Ответить

Can you please please please do an in depth video on the techno CNC stuff....

- All the bits needed for each particular step.

- Pass Depth/Cut Depth/RPM/Feed Rate/etc.

I’m brand new to the process and am trying to learn. Thank you!

Love the CNC inlay work. Can you go more into the technical details?

Ответить

I was fortunate that the algorithm sent me to your video. Great work! I will be trying this inlay technique with my DIY CNC in the future!

Ответить

Totally AMAZING!!

Ответить

I would suggest to carve ALL the male pieces first. Then carve the female parts, one at the time, glue the corresponding male part, clean up the area and repeat. This way, you don't have to remove the board and you will maintain the same Zero X and Y positions, or to use an X Y Z probe (and a CAM software that accepts it) so you can always use a corner of your piece as the starting point. Also, I was almost crying when you said that you lost an hour because of a mistake you made. I have a not so good CNC machine (now I realize how bad) and to carve the same piece you have shown, it will take me at least 4 hours, most likely more than that. The reason for this, is that my machine does not have the necessary rigidity and with soft woods I need to use 30% of the Feed and Plunge speeds (given by manufacturers) and with hard woods I need to slow it down to about 10%, otherwise, the router tilts, like when you hold a pen with 2 fingers from the top and then try to draw anything on a paper.

Ответить

And I think 60v doesn’t allow me to go very deep.

Ответить

Hey TwoMoose. Great video. I have been watching a Broinwood also. He is fantastic. I almost hate watching his videos bc he is so good. I have a question I have been doing Vcarve with female at .11 and male at .09 and flat of .02. After I trim off the male and shallow passes on drum sander, I can feel how shallow my male piece is. I want to make them deeper. Do you have have Rex’s to make deeper. I saw comments of .3 for the pocket and .04 for glue. What would the start and flat depth be for .3 pocket? Thanks.

Ответить

Great work! Glad you are able to show mistakes. Valuable learning experience for us as well.

Ответить

Cut some dowel holes for alignment. Huge job. Thanks for video.

Ответить

Sorry I haven't watched this before, Its amazing!! I love the art is it available from you?

Ответить

Amazing!!

Ответить

Great video!! Have you thought about using alignment dowels in the back side of the cutting board and into the spoil board? I use this concept for repeatability all the time.

Ответить

This was a joy to watch I would imagine these must have taken you 1-2 weeks to produce,

The mistake you made I thought you recovered very well 👌,

Love the end product please keep making more it’s very entertaining and a marvel to watch,

Have you a web sight to buy things like you produce would be very interested in purchasing

What game controller are you using for your cnc? Does it work well? I have yet to see someone use one.

Ответить

These came out amazing. Great work! I'd love to see more like this! Doing inlays is something I would love to start doing with my 1F. I haven't been able to find any good tutorials. Any recommendations?

Ответить

They came out beautifully!!

Ответить

I've very interested in learning how to create this process for myself. Just got my 1F CNC up and running and I'm eager to learn new ways to use it.

Ответить

Omg! I absolutely loved watching this process! I got a CNC for my Woodshop class (high school) and I know that some of my more advanced students would love to try something like this. I would 100% be interested in seeing more of the programming side of things if you were to post that kind of content. Thank you for sharing!

Ответить

This video does a great job of showing how CNC is not "easy" and IS real woodworking as much as someone using a table saw. The precision involved in getting all those cuts to perfectly line up is daunting, and this video showed that even someone with a good amount of experience can struggle with it. Nice work!

Ответить

So, do those larger planers eliminate snipe, or is it about the same as the DeWalt 13"?

Ответить

love watching your videos

do you have a video or doing one on how to create the inlay on easel ideally. sorry if that's been asked already

hey bro love your work.i also wanted to start this type of business and i wonder does the art needed to program or simply we can by just a picture ? If we need to program how can we learn to program the art work for cnc machine .hope i will be replied thankyou have a good day.

Ответить

wow, great design! I paused the video on both boards and couldn't tell where the "oopsie" was at. great work

Ответить

this board looks like a million dollars

Ответить

Would like to see a video on the design and how you went about in the computer. I’m wanting to try these on my CNC but have no idea where to start.

Ответить

Really nice work! I do have a question though. Rather than using a tapered ball nose bit shouldn't it be a sharp pointed engraving bit? You mentioned that you had some small gaps in the inlay. Perhaps that was because of the all nose.

Ответить

Great job! Do you use the Zank method? What size TBN are you using? I've not tried multiple inlays within inlays yet. I use a 2-flute 15-degree v-bit.

Ответить