Комментарии:

Time to retest with arachne wall generator

Ответить

it would be cool to see you revisit this option as part of a tool changing system to see if having different size nozzles would effect the printing of precise parts and their overall strength.

Ответить

WTF...

Ответить

Please, try finding a 0.05mm nozzle, I'm begging you

Ответить

You should test this with the Highly precise prusa nextruder

Ответить

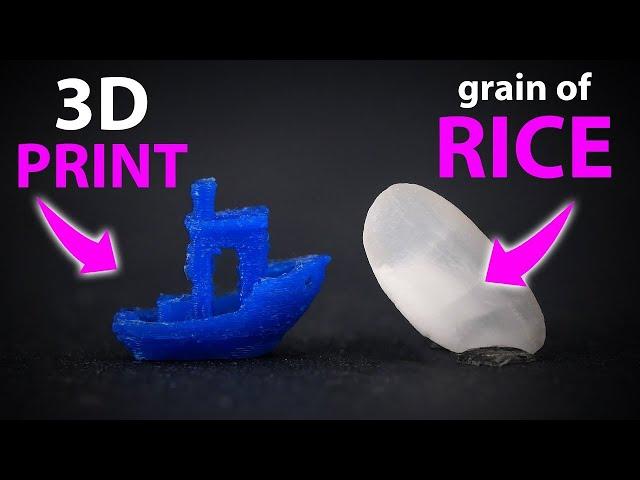

Great thumbnail 👍

Ответить

Someone had to fall on their sword for that surface finish, luckily the sword was three atoms long so he'll be ok.

Ответить

From my perspective, I'd prefer to have a single 3D printer that I can use to make large and/or durable items using a large diameter nozzle, and then also use to make tabletop miniatures using a smaller nozzle, is preferred over requiring multiple printers and post-processing machines. Especially since at the moment, I don't have a dedicated workshop room, so I'd prefer to stay away from any toxic and foul smelling options. So, small nozzles sound great. And all the problems sound like 'still better than what you have to deal with in the resin world'.

Ответить

This comment probably will never be seen, but after buying both an fdm and an sla printer : micro nozzles will never be anything more than a gimmick, something you do just because it's dumb and you can do it. Sla printer start at the same price as any decent fdm printer, are 100 times easier to set up, no assembly required and will give you really detailed results with little to no setting tweaking, and almost invisble layer lines. (Completely invisble if you paint over it.) If you want small intricate prints, there's absolutely no contest, sla is the way to go. At this scale, fdm layer lines are straight up impossible to remove cleanly. I haven't tried acetone vapors, but I strongly belive the size will make material puddles on the print and ruin it, rather than just smoothing it like it would on bigger objects.

Fdm isn't obsolete at all though, resin is pretty brittle while pla is strong and durable. On large scale objects like cosplay parts, or decoration items the layer lines are more negligeable and easy to smooth out with sanding paper. And cosplays are a good example of when you should sacrifice a bit of detail for the sake of strengh, resin wouldn't hold up to any kind of shock cosplays can get. But again, at this scale fdm printers can handle details just fine, so you're not really sacrificing anything you're just gaining durability. Hope this will help someone stumbling upon this

I am looking for a partner (preferably in Silicon Valley) interested to design a cutting edge FDM 3D printer. I am an engineer in Photolithography (work at ASML), PhD in engineering mechanics. not much experience with 3D printing. we can brainstorm, read state of the art and decide what direction move.

Ответить

I'm printing with a cheap .1 m nozzle on an ender 3 v2. I'm using it for detailed earrings. It's possible. It's actually more difficult in Cura than it used to be.

Ответить

50 us for one Nozzle ??? 35 for a 0.4 mm nozzle ? Well , i have no doubt tgat they ate excellent nozzles , but i get very good results with normal cheap ones

Ответить

Ich sag ungern ,deswegen auf deutsch.

Japanisches mit der chinesisch imitierten billig Musik zu präsentieren ist wirklich nicht zeitgemäß....

It's at that moment he realized the importance of .9 stepper motors.

Ответить

Resin printing sounds so nice but after you look into it then you realize the huge down sides of it.

Ответить

Imagine the detail you could do with these

Ответить

Shoutout?

Ответить

I think I would pick resin printing if I needed a small detailed part but fdm for pretty much everything else.

Ответить

Good luck cleaning that

Ответить

What if you had a duel head printer and you had one with a 0.4 and one with a 0.1 then interchanged them when you want high quality or not, and you could determine what is high/low quality the same way we use support blockers in slicers.

Ответить

You have a really friendly smile!

Ответить

OMG how do you clean this nozzle

Ответить

I wonder if they could use an acupuncture needle with an edm to cut the hole.

Ответить

How are micro nozzles perform at printing fabric patterns/structures? Would be dope seeing some printed micro fabrics

Ответить

The chatter on the last part of the 0.15mm nozzle can and will increase the surface area creating a larger meltzone ;) physics is cool

Ответить

I have a couple .2 mm nozzles. They worked great for what I used them for. Takes forever though.

Ответить

I bought a 3d printer to tinker and prototype, never thought I would get sucked into this rabbit hole.

Ответить

As someone who owns an Anycubic Photon Zero, I 100% agree with you about resin printing. I literally haven’t used it in years, and I currently don’t even own a working FFF printer.

Ответить

Ausgezeichent :)

I think such small nozzles wille be useful for bioprinting - blood system ir nerves.

Here is why dogs and 0.2 nozzles are not compatible. At that size, a failure point can be my dog coming in to my workroom, shaking and in the process release all the particles, just all of them, then a while later you can be sure one of the 0.2+ sized particles manage to find their way in to the enclosure and bam clog.

Ответить

detail = resin or strong = FDM

Ответить

Biggest problem I have with resin printing is due to a long battle with kidney cancer I'm left with only 1/3 of a kidney and my doctors warned me that chemical exposure could damage what I have left.

Surprisingly even though I have so little left I'm told it has 47% function and I won't need dialysis for the time being.

I'm hoping the new types of resin will reduce the risk otherwise I have to wear pretty much hazmat gear to handle it. If anyone has an idea of how to deal with this I'd appreciate it. I hate the idea of my investment going to waste.

How small of a print in place model could you do with this, and could resin beat that quality?

Ответить

I highly recommend the 0.2mm nozzle from Micro Swiss.

I get extraordinary quality and detail on my small parts.

Just use for small parts as time-to-print will skyrocket!

Fascinating and am surprised at the amazing results that are possible

An interesting application would be to use a printer with two different nozzle sizes. Either a two-nozzle printer, or first printing with larger nozzle and swapping to add final details on top surface.

There is probably some interesting situations where using a nozzle size between this 0.1mm and more traditional nozzle size. For example, would expect layer bonding strength would be enhanced at smaller nozzle sizes.

I have some cheapo .1 nozzles, I think I'm gonna try it out.

Ответить

I was doing some pressure washing and noticed the nozzle oriface size could be adjusted on the fly. Further I use to do co-extrusion using multiple nested orifaces, has anyone done anything similar in 3D printing.

Ответить

My takeaway is resin printing resins need to be better characterized , I am very interested in fire resistant plastics for electrical switches , and resin printing seems a obvious way to go but the lack of information about the resins is a real problem.

Ответить

50usd? I 💩 50usd

Ответить

do you know if upgrading a printer to something like an ultimaker S3+ would help with the small prints? im trying to prototype it with 4mm by 4mm sized parts and they just come out bad even with 0.2mm nozzle on my ender 3

Ответить

What if you use a double extruder setup with a big nozzle for the infill and a tiny one for the surface?

Ответить

Jfc

Ответить

I think if you're trying to print something that tiny, then FDM is a complete waste of time. As can be seen the results aren't great with imprecise layers, ringing and stringing. Just use a resin printer.

Ответить

That is pretty average. I don't know what you're talking about. That's normal.

Ответить![Kyle Bostrom [Rubiks_20] Kyle Bostrom [Rubiks_20]](https://ruvideo.cc/img/src/anItb24tZmZmZmZmMDB4MGMtay1jLTA5cz1NXzBCVkJmZnFZZmVMSUJkZk9oR1QtNW90T2xUWWJMNjB0amF2ajM1VjlSRjJxSFFIa19nMkdnOTY1VGJqNDhOVmVTSUoxQVMvbW9jLnRocGdnLjN0eS8vOnNwdHRo.jpg)

Why didn’t you put all of the printed 3D models in the description?

Ответить

Right on shhh te faun 😊

Ответить