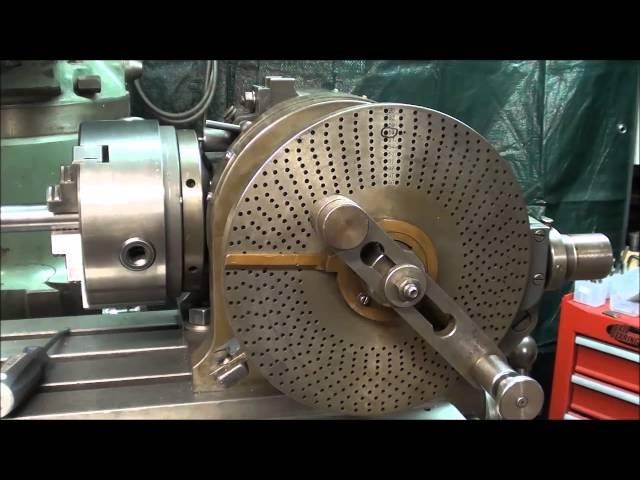

SHOP TIPS #198 Gear Cutting on the Bridgeport Mill Plain Indexing Method tubalcain

Комментарии:

I haven't worked in a machine shop for 45 years, and my reckoning skills are creaky. I watched this video because I'm selling Bridgeport mills with attachments and tooling for a tool & die maker who's in the old folks' home...and it is thrilling! Real, concrete, factual work, an antidote to know-nothingness! Thank you. Can't wait to show it to my friend, too.

Ответить

Great👌

Ответить

Mr tubelcane

Ответить

Most excellent.

Ответить

I sure do enjoy your lessons Sir.

Ответить

Today on traning i try to create ty for video

Ответить

الشكر بلا حدود والتقدير فوق طاقتى وجزاكم الله خيرا وجعلكم المثل الأعلى لكل مخلص وامين معلومات قيمه ومفيده ونحتاج المزيد

Ответить

Now do it in 1/4 the time.

Ответить

Hidy to ya. I appreciate all your work. Thanks for showing formulas & what they do and how they pertain to actually cutting the material. Thanks for narrating the videos so nicely & being clear about everything. And finally, thank you for all the prep work and setups and the editing and posting of the videos. THANK YOU ! YOU ARE APPRECIATED !!!

Here's a tip, you probably already know, you can get permanent Sharpie-Marker off of most surfaces by scribbling the mark with a DRY ERASE MARKER, and then immediately wiping it all off with a good quality paper towel. It works best on non- porous surfaces.

I used to be a Machinist / Tool & Die Maker and switched careers where I got a good paying and stable job as an Electrician. I still practiced machinist things, but only as a hobby. All during that time, my spare time I was always on call for Volunteer Fire & Rescue. I'd jump & run at a moments notice, (if I wasn't at my job. I told the Fire Chief, when I was on the clock at work, that he wouldn't see me standing on the tailboard.) I did fire and rescue, till my back got banged up at work. I reluctantly came out of the fire Department. I did 21 years in it & almost 38 years as an Electrician, before I retired. My balance is gone and my health is kinda-ok.

I still do some lathe work and make or weld up something and re-work parts to keep my equipment operational. I'm working on a center pulley movable base for a drill press, now. I've got it out of the machine. Now to figure out how to get it out of the mount, as it's dropped into the pulley. I'll eventually find a video on that.

THANKS TUBAL CAIN

Great/clear explanation of the indexing tool!

Ответить

You know I made some gears using direct indexing.... it just so happened I needed some 24 tooth gears for a project that I'm building so I lucked out on my first gears and was able to use direct indexing but the question is really unrelated I used a Chinese Arbor that has multiple bushings up and down the thing and they all seem to wobble during the operation there was nothing I could do to steady them...

Weather this had any affect on my gears finish or not I am not sure. I guess all I'm asking is this normal for these bushings to not sit quite right? I mean they seem to hold the gear cutter in place fine I guess that's all that really matters but I was just uneasy about the whole thing and wanted to ask an expert their opinion so that's what I'm doing.

I think that I have been doing everything manually for enough years that it's time for me to get a digital readout for my mail I think it's past time as a matter of fact if anybody has any suggestions as to a good brand to buy I would be very receptive and grateful

Ответить

I just saw the light !!!!!!! thank you ;]

Ответить

Grandpa? I love your video, great job sharing your experienced. Look forward seeing your next either helical/spiral/hypoid Bevel gears on how to calculate, build & cut gears on that. This is really very simple to understand without confusion. It's really great to keep up a good work sharing that to us.

Ответить

Can't thank you enough for these professional quality lessons. They have more timeless value than you could ever know. You remind me of a classic shop teacher from back in the day.

Ответить

Thanks so much for the video!!!!!!!!!!1

Ответить

Very nice sir

Ответить

phantastisch mr pete

Ответить

That was so interesting, thanks.

Ответить

Excelente explicación , tu libro de consultas donde lo consigo y cómo es el título?

Ответить

Thank's for the video sir very informative i'm learning🙂

Ответить

Ohh Mr. Pete your too funny!...... "Count out loud to your self "

Ответить

usrful vedio for bigners

Ответить

I am lucky man using metric system

Ответить

Hi, You should watch " This Old Tony " and check this video out ( 15T-M2 Let This Be A Lesson To Ya! Sept 2nd 2017 ) The Module is the category of the cutter size, they start off very small for watch making, M 0.2, I think , and go up to big sizes for gears in Lrg transmitions, M5 Etc. There are about 15 different modules. Chinese Mini Lathes are usually M1, I have a 12" swing 1200MM bed the gears are M2, My Taiwanese Mill is M2.5, Etc. This Old Tony gives the best explanation of any videos I have seen, so check it out. He tells you how to choose the gear blank Diameter by number of teeth Etc and easy way to calculate dividing ( Plates ) on your dividing head.. All other videos I have seen are based on repairing or replacing an existing gear with no explanation of how they derive at their measurements. Any body can copy a gear as I have done heaps of times. Hope this helps.

Ответить

Bhai is me 70 ya 80 gear divid karna hoto kaise kare ge

Ответить

Bhai is me 70 ya 80 gear divid karna hoto kaise kare ge

Ответить

I need to make some metric change gears for my import lathe, which needs a Pressure Angle of 20 degrees and Module 1.5 (about a 17 Diametral Pitch). Since these gears only turn the leadscrew and are not highly loaded, do you think I could get away with Delrin or even Aluminum? You see, my involute cutter set is also a cheap import... 😏

Ответить

I always search Martin sprocket and gear to see if they make the gear blank needed. If so, I search that part number on ebay. For instance, that 30 tooth I can get for $24.50 on ebay. From there you can machine its physical shape to whatever you want. I enjoy making parts myself but like they say, time is money!

Ответить

Excellent video!

Ответить

Do a helical gear please

Ответить

ask permission to share

Ответить

Me too

Ответить

Taught like a professor thanks

Ответить

Great teacher,thank you.

Ответить

Very clear!

Ответить

I have that DRO and my top display only has the line on it like yours does, is there an issue with yours or can you help me with my issue so i have two axis readouts. Thank You for your video and your help.

Ответить

Great video! Just for clarification plain indexing is also know as simple indexing.

Ответить

you are great man thanks alot

Ответить

My question is how to cut same gear with shoulders on both sides to aid in preventing belt run off. Thanks for your time !

Ответить

Good Video. I could see the cutter running out of round both vertically and horizontially. I'd have to check both faces of the cutter and see if center hole was drilled dead center. Must have been made in China !

Ответить

It’s a foreign cutter and you’ll quickly doll it!!! 😂 loli

Ответить

how to get away with the backlash on dividing heads. i have seen theres some backlash in my dividing head's worm reduction

Ответить

Mr.Pete what if I am going to make 2 slots (0 and 180 degree) using 15 holes plate.(20 complete turns). Should I still not count the hole where the pin is engaged? Thank you!

Ответить

Nice video

Ответить

So well presented and explained. Now, if I just had a mill and an indexing head...

Ответить

is the module distance between gears the same formula?

Ответить