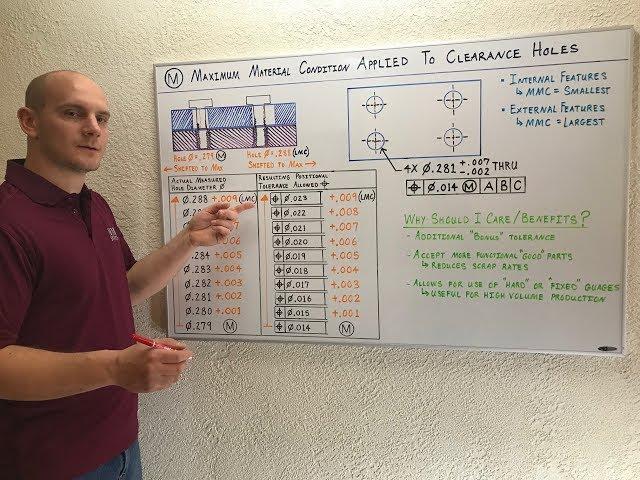

How GD&T Maximum Material Condition (MMC) Works with Clearance Holes

Комментарии:

Hi, your explanation very clear.thank you very much.

Ответить

Dude this unlocked this concept for me. Your visuals definitely gelped more than others. Thank you sir!!

Ответить

Great video🔥. Can someone explain WHEN to and not to use modifiers?

Ответить

How you draw all this up on that whiteboard is alone a reason that this could be a viral video on MMC. Well done.

Ответить

thanks for your video, my problem is the pattern holes interfere each other when we use tolerance bonus.

Ответить

Hi STPE , what would the gage be made at? That is where I get confused. Would it be LMC or MMC ?

Ответить

I think you are forgetting that the .014 is a DIAMETER. You can only be out in one axis a total of .007 @ MMC while being dead nutz in the other axis.

Ответить

Bless your soul! I can't tell you how many ambiguous videos I watched about this topic that only left me with more questions. This all made perfect sense the first time I watched it, was very organized, and as your channel name puts it, straight to the point! Thank you so much for your efforts.

Ответить

Thank you for the explanation of relationships between hole size and hole position. This is the first video of many on MMC/LMC in which I could visualize what's going on and make sense of it.

Ответить

The explanation is clear and easy to understand.

Ответить

Hey sir, great explanation with real consequences of not following MMC while drawing. I request you add microphone for other lectures.

Ответить

Does it work for both directions? Ie position shifted to the left Or right?

Ответить

Does the tolerance work the same for external features just like how you drew up the table for this part?

Ответить

Just found this video.

First, l am not an engineer in any capacity but to me, the hole size for the fastener is predetermined by the size of the specified fastener, the minimum drill or reamer size to allow the fastener to pass through the material?

The only other factor to consider is the minimum specified flange/shoulder/plate size surrounding the hole that the fastener fixes unde compression.

Otherwise you would be into making a special size tool and fasteners which isn't always cost effective.

No doubt and hopefully some can show me the errors of my thinking if any?

Absolutely perfect explanation and that is the best whiteboard I have ever seen!

Ответить

Excellent. I'm subscribed. Great videos on GD&T.

I have taken both the Fundamentals and Advanced GD&T courses from AGI. Your videos are a great way to see the theory explained in practice. Thank you.

Quick question?

when the actual measured hole diameter is right at .281 then shouldn’t it be +.000 , instead of +.002? Therefore at .288 +.007 LMC , instead of .288 +.009 LMC . This would effect the values in the positional tolerance side of the table as well. Possibly there is a mistake and you’re adding the whole tolerance spread of .009 when it should be just the .007 on the plus side. Let me know what you think , thanks

I like the table method here where you can see the relationship between the values. Much easier than a formula.

Ur looking like jony s...

Ответить

Hey bro. this is the best video on mmc modifier. I would really appreciate if you could make more videos on GD&T.

Hats off!

I have been always struggling understanding MMC and LLC in drawings. Now you decoded that for me for ever. just don't know how to say Thanks you. very appreciated man. God bless. keep it up

Ответить

Excellent explanation, Really helpful. Thank you!

Ответить

Very good explanation. My Q.C. lead doesn't understand what the MMC symbol is.

Ответить

Much helpful

Ответить

thank u so much for explanin this in so simplistic way. gbu

Ответить

You are the only person explain MMC completely in YT

Thank you

awesome!

Ответить

Such a good explanation

Ответить

This is a great video.I don't usually comment but wanted to let you know

Ответить

Great video.

Ответить

Excellent explanation. Thanks...

Ответить

clear explanation. thanks!

Ответить

Taking a peek at this right before walking into a job interview, lol. Refreshing my memory after a year off of work.

Ответить

Thanks bro you saved me 700 bucks

Ответить

wear a mick buddy

Ответить

This helped a ton. How lucky are the students who have you as their professor?? If only there was someone like you in every machine shop.

Ответить

you're awesome, great video. it's helping me through my first internship! thank you

Ответить

This explanation was amazing! Thanks a lot.

Ответить

Thank you.

Ответить

I'm almost to my midterm for my class and I still have no idea what is going on. This video was extremely helpful, will be checking them all out.

Thank you!

HI! I have one question. Can GD&T using on plastic parts (molding parts)? I think it only suit on CNC parts, because plastic parts tolerance will change follow the different dimension.

Ответить

Really nice explanation!

Ответить

I just saw this very informative video and I have a question for you and would like your opinion.

What do you think about a true position tolerance of . 0004 with a bore that is+. 0002/-0.0?

I'm thinking this is not a realistic tolerance, what is your thoughts?

Just amazing!

Ответить

thank you sir

Ответить

Brilliant teaching. Not everyone is gifted to teach in a way that people can understand. You are the best with it. I'm a mechanical engineer. Right now, I'm trying to learn GD&T concepts in order to understand CMM reports on the inspected parts.

Ответить

goat

Ответить

Hello sir

Your explanation is very clear