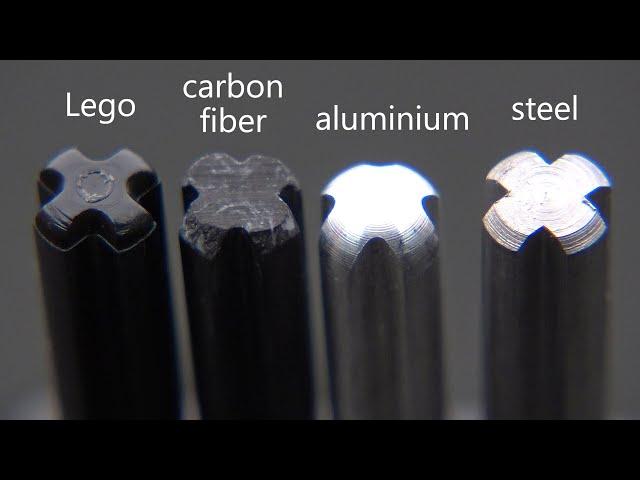

Testing Lego-compatible Axles (max torque, durability, friction, etc)

Комментарии:

Какая бессмысленная хуйня.

Ответить

Was... Machts du... In there?

Ответить

For the sound test i think it needs to be redone. You should spin it the same way you did in the test before it for more consistency. Then measure the maximum, minimum, average and median sound for each. All four metrics matter to different scenarios. Itd be awesome to see this data in a later video

Ответить

Makes you wonder why people use carbon fiber driveshafts

Ответить

Это уже больгые люди, психушка плачет пл ним

Ответить

Люблю лего. Но иногда покупаю и аналоги. Вот бы их сравнить.

Ответить

Video totalmente estupido

Ответить

Your Lego automation builds are next-level awesome! 🌈👾

Ответить

Aluminum & 3D Printing has High Profit Margin

Steel is gud 4 Recycling

Steel wins neg difficulty

Ответить

For the friction test, isn't the distance the car reaches also influenced by its mass? Maybe the difference of mass between the carbon fiber car and steel car is negligible?

Ответить

The noise test didn't show any detectable difference in volume, but the frequency of the noise changed with materials.

Ответить

There are a few things that will make the steel stronger. First, cut a radius notch, not a sharp square notch into the steel. This will avoid stress concentration. Secondly, that steel seems quite annealed. A bit of heat treatment should strengthen it considerably (depending on what steel it is). Third, the kind of steel used. This looks like 302 stainless. Its UTS is around 70ksi if I recall correctly. I would try something like Maraging 250 or 300, or Aermet 100, or 13-8 stainless. Finally, it has been machined. I would consider a forged piece.

Ответить

love this video but maybe you can just release the car from the same point instead of pushing it to reduce variables

Ответить

Here we are, 3am.

Ответить

"Детский конструктор"

Ответить

Самое лучшее из пластелина!!!

Ответить

cool

Ответить

Watching the carbon fibre just to see it was UD hurts, try get a block of short chopstrand and machine it into shape, will give it a half decent chance

Ответить

the second experience doesnt really make a lot of sense as the other materials have higher degrees of hardness than plastic so they will always scratch the plastic and not the other way around

Ответить

A few tests that I disagree with:

Noise test - Unlike the spinning plate friction test, the parts were spun by hand. This introduces another variable to the system, that being the starting speed. It's no wonder there was no clear difference, when the starting speeds varied.

Insertion test - Again, you did this by hand, making this more a test of your own dexterity than a test of the part's performance. Speaking as someone who's built a lot of lego, sometimes you just can't seem to get things lined up. I'd replace this with a lateral friction test, where you use a motor to push the rods into the parts at a steady pace and measure how much force it takes for each rod.

With all this metal Lego you're making you're getting close to inventing Meccano

Ответить

There is something about this channel that makes me believe that Lego could pivot and make actually usable prototyping kits. It feel tantalizingly close to opening up a whole new world of DIY problem solving. Usually when I get this feeling it's because I haven't understood a MAJOR constraint or cost problem that would make it impractical or unaffordable. But if Lego hit the sweet spot, it would really open up some doors.

EDIT: I just looked up Lego Technic and it is kind of baffling to me that they don't sell a general prototyping kit (especially with the community that seems to be present) I was thinking about how one would have to make a "Technic" style system that would give you the HIGHEST number of possible working configurations. It's a problem that is mathematically beyond my capability but it seems like it would have to be based off of a starting length and everything being built on its multiple (possibly a length that is a multiple of an approximation of Pi (the number) so the gears would fall into the correct locations)

So there would need to be kits based off of the module of the gears used that would be linked to the axial size that would set the spacing of the Lego "buttons." Then adapter plates that would allow you to snap in assemblies of a different module to a larger system (preferably the modules themselves would be multiples of each other such that your adapter plates subdivisions would end up snapping into useful spaces).

Is it just me or does it seem like if someone really understood how to solve this problem they would also have a good insight into how the universe itself functions? It's all ratios of some "quanta" or "Planck length" right? Did someone slip me LSD? What's in this coffee???

This entire video: "If resorting to brute force didn't work, you didn't resort to enough of it".

Ответить

this feels ilegall to watch

Ответить

Lots of uncontrolled variables

Ответить

But what is it in Freedom units?

Ответить

maximum torx is when axle start bending not when its broke. lol

Ответить

who are you?

Ответить

Thanks a lot 😊

Ответить

и н6а куя мне это

Ответить

Titanium?

Ответить

How not to give this fella a thumbs-up?

Ответить

N-m посчитали неправильно. Если бы пластик сломался от 0.8 NM, эту деталь можно было сломать голыми руками. Даже ребенок)

Ответить

I’m extremely surprised that you don’t have better quality hex keys. I’d have thought you’d be a Wera, or a PB Swiss man

Ответить

Repent to Jesus Christ “Let the peace of Christ rule in your hearts, since as members of one body you were called to peace. And be thankful.”

Colossians 3:15 NIV

Why am I watching this?

Ответить

I have no idea why I watched this video but it was enjoyable 👍

Ответить

Only thing I dislike is no scientific method, one test ain't to enough. 5 attempts, take off outliers (best and worst) average remaining 3.

Also I thought lego were made out of ABS not POM, I'm guessing low friction plastic makes more sense for axles (but if so, I'd be interested in how PTFE axles compare)

now this is just my opinion but it looks like if you need more durable axles get the carbon fiber cause anything higher will cause the rest of the system to be the failure point rather than the axles which should be the easiest part to replace normally

Ответить

How were these attached to the table?

Ответить