Комментарии:

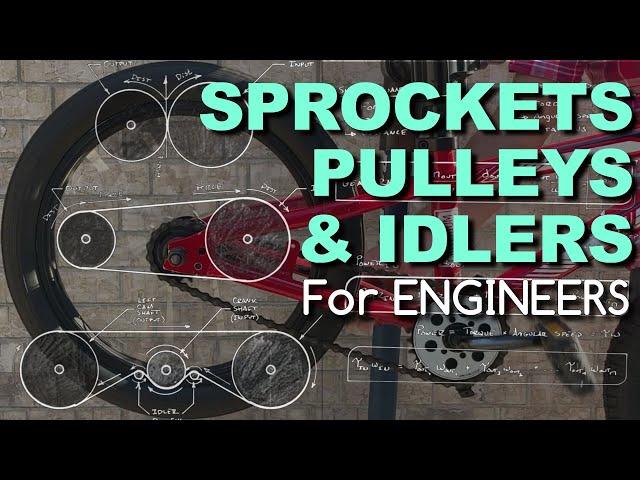

Add a practical. How to choose and match chains, belts and cogs to one another.

Ответить

You should do a video, if chain size like a 35 chain & a 428 with same gearing have the same impact in speed/power & if you can go higher gear ratio with a bigger chain size like 428 & get better speed & power then a 35 chain.

Ответить

If you take the strength of the material out of which the gears are made, and the surface area where gears are meshed vs. the chain surface area touching the pulleys - there is yet another major difference between these two. Of course for this we also need to look at friction and we cannot just neglect it.

Ответить

Im a little late to the posting of this video, but how would one calculate the tension in the chain of the systems shown in the video and how does this change in the tight vs loose sides of the chain?

Ответить

hot water?

Ответить

I know it's too late to ask you but I will try my luck.

is it ok to have multiple chain drives connected in one motor because I haven't seen any?

This is a great video, and l like your lettering.

Ответить

If I add a jackshaft to a chain drive just to gain offset to accommodate a wider tire and the jackshaft has the same number of teeth on both ends, will the number of teeth on the jackshaft change my final drive ratio? Thanks

Ответить

I'm going to be building a homemade vehicle (car & light truck) tire changing machine but instead of making it manual, where you have to pull the bar around the center post to install or dismantle a tire, I'd like to motorize it. I'd mount the motor under the platform that the tire sits on and either have it turn the bar around the tire or make the bar stationary and have the motor spin the tire (and platform). I need it to turn the bar or the tire fairly slow, maybe one revolution in 10 or 15 seconds so I need a high torque but slow rpm at the driven pulley or sprocket (I'd like to run cogged pullies with a cogged belt). Without getting technical about it I'm thinking that an electric winch with a pulley connected running a belt to the driven pulley turning either the bar or the platform but I'm not sure what size pullies I would need. I also thought about getting a high torque windshield wiper motor or a similar gear reduced 120V motor but I need to figure out what size pullies I need to keep it high torque but not run the bar or platform so slow that I can pour a cup of coffee and drink half of it by the time it makes one revolution but also not so fast that the white on white lettered tires doesn't just fly off 😆! But seriously, I need to figure out the pulley sizes I need to allow it to turn in a slower controlled manner but still have enough torque to do the job.

Ответить

Great explanation and content. Thanks

Ответить

Great tutorial. Exactly what I wanted to learn. And, the lesson featured the mathematics. I am replacing the rubber belt on an air compressor with chain and sprocket.

Ответить