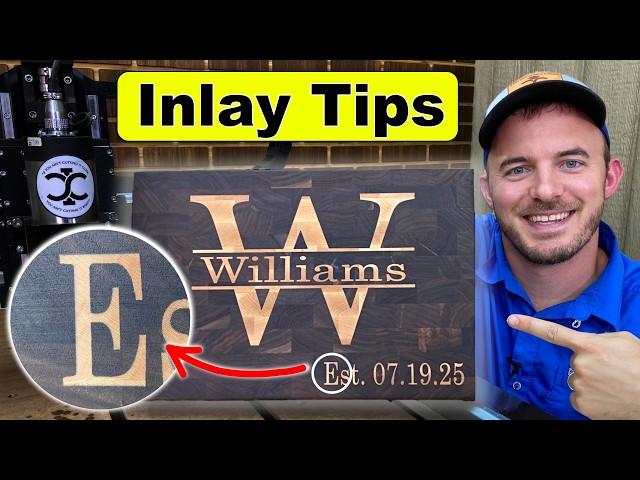

V-Carve CNC Inlay Tips (That ACTUALLY Work)

Комментарии:

Z height issues happens, but the bit survived.

Ответить

Love the video Ryan. I’ve got an Altmill on the way so I’m looking forward to taking on some projects. 2 questions: have you ever used composite nails in lieu of screws as a hold down? And what would be the best way to cut multi layer “mandala” style projects on a CNC, or is that always going to be better done on a laser cutter?

Ответить

Good morning. Ryan something to consider for your videos. I would suspect that you receive some if not a lot of views from Christian's who watch them. For those viewers that are please don't use the name of my Lord, Jesus Christ as was done in this video in a blasphemous way. Not giving it due honor. While it may hold no meaning to you for those of us that are saved it means everything. "Neither is there salvation in any other, for there is none other name under heaven given among men, whereby we must be saved." Acts 4:12 You are welcome to delete this comment after you read it as I'm not trying to distract from your CNC video....but want you to consider some of your audience.

Ответить

You make it look so easy. Thanks for sharing and for making the kits. I don’t have the tools to make end grain panels

Ответить

Ryan Great video!

Ответить

Thanks for the advice and lesson on inlays. 🎉🎉🎉🎉🎉🎉

Ответить

How do you setup to cut the plug off the top of the cutting board. No videos on how to setup to cut the plug.

Enjoy your videos

Thank you

Another great visually descriptive video, Ryan! Thank you!

Oh, and, uh, kinda happy to see that you still make those tiny, but oh so scary, miscues on the many steps of running a CNC project. Heh, that Altmill high speed move through the material would have given me a heart attack.

The screws were a brilliant idea!

Ответить

What is the total run time for the male and female? also what toolpath did you use to cut out the male plugs? thanks

Ответить

beautiful & clean work. Thanks for sharing this tutorial

Ответить

Every one of these tips helped tremendously. In fact, it cleaned up the end result on the material. Thanks!!

Ответить

Excellent video, Ryan! Thanks for sharing!

Ответить

Gran bel video Ryan. Volevo fare solo una osservazione: certo che 0.23+0.1=0.33" fatti in una unica passata è uno sforzo non indifferente sia per la fresa e sia per la macchina. Dividendo il percorso in 2 o 3 percorsi intermedi rispettando necessariamente la sommatoria originale, ci sono delle profondità intermedie da rispettare o no? Grazie per la condivisione e continua con il tuo entusiasmo.

Ответить

Great video! I'm just curious why you decided not to use the vcarve inlay tool path and instead used the "old school" method?

Ответить

Thanks Ryan. An excellent video. I am grateful for the amount of time you put in to making these very professional (including "awshits") videos.

Ответить

The press file is awesome. The press clamps are no longer on Amazon. Can you please recommend a replacement?

Ответить

Could you not shellac the end grains of the boards? Do you have seal all edges or just end grains?

Ответить

G,day Ryan, Great video, it's always good to watch and learn from you. Obviously, you're using a V-Bit, but I did see a brief short video of yours where you did an inlay using a TBN bit, but you didn't elaborate on how it went, or any of the details of how you did the inlay. Can you give me the link to the complete video? Thanks Ryan

Ответить

Note that the new toolpath in v12 is superior: having a large "Start depth" can be a problem if your bit can't handle it. The new toolpath doesn't have this problem

Ответить

My tip: I use a 20 ton press. I press it, come back 30 minutes later, and press again. During that time, Some glue will ooze out, some air will leak out, allowing me to press even more. Having a mighty press like that makes a world of difference and allows my machining to be mediocre without affecting the final product

Ответить

When I create a boundary, I offset to the outside about 2 inches first, then offset that vector inwards 1.5 - 1.75 inches. That gives you a more rounded outside profile for your male plug clearance, and saves the step of creating fillets on the sharp corners. Makes things much easier if you are using a bandsaw to cut out the part.

Ответить