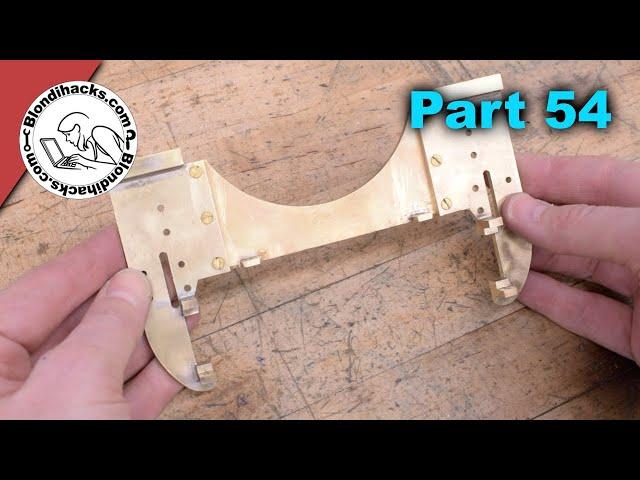

Motion Brackets - Pennsylvania A3 Switcher, Part 54

Комментарии:

"Impressive" scrap bin. - I get in a war whenever my sons want to clean out the scrap. -I say "What if we need a piece 3/16/by 3/4, cut it off a 10 piece of bar stock. . - They say, YES,,,,,and you know what, They are right, But I still tyy to hide my coffee cans full of useless scarp.

Happy Ney yea and God Bless to everybody.

French viewer here, still enjoying every bit of your progress. Useless fact, around here we call that "french curve" tool a "parrot".

Ответить

It’s a shame you couldn’t work “make the noise” into this episode, but I’m holding out hope for future videos. 😊

Ответить

Artisan bandsaw nicks... Sounds like a '70s band. Love it. ❤

Ответить

"In Colour ... Today we're gonna make a bracket. Binky-Level bracket!" - Hilatious

Smells like Bad Obsession Blondihacks.

I wish you and your family a Happy New Year. Greetings from Germany.

Ответить

I’m here for the day a moose sticks its head in the window during the intro.

Ответить

you are just a wonderful person!

Ответить

Loving the image of the part in the top left corner!

Ответить

While Quinn makes the bracket I'M going to get the lead out

Ответить

Love the fact that you watch BOM!

Ответить

In colour, nice! Thanks Quinn, great piece, helps a lot!

Ответить

The advanced use of CAD (Cardboard aided design) for those French curves made my day. Also I’m sure Nik approves of your bracket!

Ответить

Looks great! Imagine the results you'll get when you do know what you're doing :)

Making silver soldered brackets oversized so I can mill them to dimension is something I have not learned to do yet. One day I'll get it right.

In boat building the saying goes "if it looks fair it is fair and you can only ever see one side of the boat at a time". ,😜

But that's from the time of tree butchering...

the disappearance of sharpie marks when heating is a good indicator that you're approaching silver solder melting temperature--it's within a few tens of degrees. thanks to my jewelry making instructor for that tidbit of info, she was amazing in all ways

Ответить

those artisan marks would add at least $18 thousand (Canadian) in a gallery. If they were visible, only two or three thousand, but with them hidden it brings it into the special know category. People pay a lot extra to be that special.

Ответить

Fascinating machining.

Ответить

Does the Thai Plate come with a spring roll?

Ответить

When you acknowledge your “dumbness” you give us permission to accept our own dumb actions. Then they simply become part of the learning curve. So, thanks.

Ответить

That turned out very nicely. Or should I say, that milled out very nicely. Ha! See what I did there? Yeah, ok. Sorry.

I am still amazed at your ability to do the little tiny fiddley bits. Beautiful.

Thanks, and Meow to Sprocket.

And hope you had, and will have, a Merry and a Happy...

Why did I never think to deburr my scrap and offcuts before they went in to storage? I need to pass that along...

Ответить

The race is on now to see what will get finished first, Quinn's locomotive or Curtis' crane 😂

Ответить

The first thing that struck me when you dry fitted the loco together at the end was how effective that tie plate was as an airbrake! Aerodynamics were not part of this locos design! I wonder how much energy has been wasted by the railways pushing 'bricks' through the air?

Ответить

Beautiful work. Nicely done. You’ve come a long way!

Ответить

Binky level brackets in colour!

Do we all watch the same content?

Yours is best.

You made Binky proud🤠

Ответить

It’s not a Binky level bracket unless Tea and Biscuits are involved 😊

Ответить

Great video , thanks for posting

Ответить

Tack!

Ответить

Nice part! : D

Ответить

Man that was some cool shim stock. Why didnt someone thin of that sooner?

How does it weld tho?

Very nicely done Quinn, thanks for the video.👍👍

Ответить

I like you

Ответить

I miss the hands. I know time moves forward yada yada but “and thiisss is blondihacks” is quiet comfort to me. ❤

(I’ll settle for occasional hands tho)

I'm with you. deburr you off cuts.

That's another thing that separates us from the animal...I least the ones I work with...

A Binky level bracket, ooooh.

Where did you find an angle grinder that takes a 1/2 inch cutoff disc?

I'm very impressed with your CAD skills

Once again, a beautiful job on a tricky part, Quinn! Nicely done.

Ответить

That is a very cool looking part. Nice work!

Ответить

Love your sense of humor, Quinn! Thanks for another great video!

Ответить

Wonderful!

Ответить

54 episodes of wondering and I finally gotta ask - why do you always specify “silver soldering” vs just “soldering?” While it obviously involves solder made from silver rather than tin or lead, it doesn’t SEEM like the actual process is different in the way that, say, “TIG welding” is different from “stick welding.” But maybe it is a sufficiently different process that you feel it’s important to specify? Alternatively, let’s say steam engines should only be oiled with synthetical oil, I could totally imagine that instead of always saying “oil the parts with synthetic oil” someone might just say “synthetic oil the parts.” Is it more like that? Or is it just about avoiding the “soddering” issue?I know this is a dumb question, but…

Ответить

Thank you so much I love your videos❤

Ответить

Wow really starting to come together. Nice job, I look forward to seeing the progress each week.

Ответить

You know, after watching this since the beginning, I think it'd be cool to see you try a skeleton clock with some complications. Then again, you may wind up cursing me if you try it.

Ответить