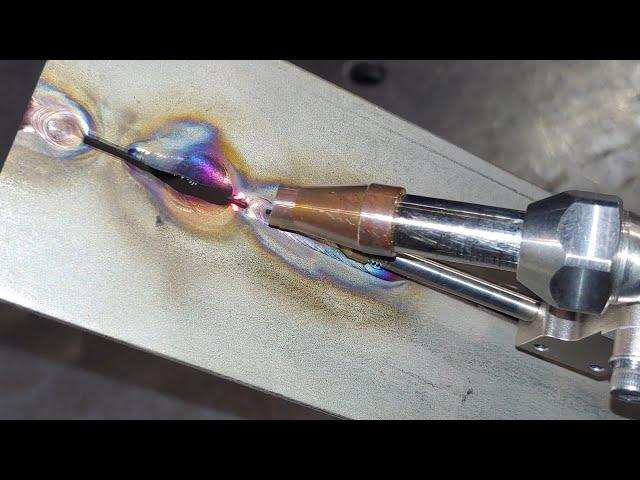

Is it impossible to laser weld an open gap?

Комментарии:

Muito bom os esclarecimentos.

Ответить

Can Copper and Brass laser welding ..??

Ответить

Would like to see a follow up video on a strength test please, on one of those pieces that you weld. The public like myself need to know how strong those weld are!! Nice video on the test pieces👍👍

Ответить

Muito bom!! Será que solda ferro fundido?

Ответить

For stupid Americans, the dude is speaking Korean. Not Japanese

Ответить

Bom dia. Está máquina está disponível para venda no Brasil. E se positivo...qual valor?😊

Ответить

I can do laser welding with gap. No problem. Need to adjust filler setting and style of welding.

Ответить

wow impressive

Ответить

Que precio y donde se puede adquirir el equipo de soldadura láser

Ответить

Great content. Very helpful. Thanks a lottttt!

Ответить

Jelek bos.. Hsil las dekok.. 😆

Ответить

이면비드 나오나요?

Ответить

Excelente maestro una consulta , en cuanto a resistencia la soldadura laser es mas fuerte debido a que es a nivel molecular ??? O no ay tanta diferencia con la tig

Ответить

Who makes quality laser welders and what is the price point?

Ответить

My Korean aint so good, but his finger wagging was easy to follow😂 Kou-mop-sue-me-dah

Ответить

But at the 4.37 min the material is changed. Much smaller gap on the second piece of material. The gap on the first one is really difficult to fill it.

Ответить

레이저용접기 ㅋ굿 티그용접사 좃됫구나ㅋㅋㅋ

Ответить

mira, mira again again i heard always saying mira”

Ответить

This video shows everything is possible

Ответить

2 things. First let's see the back side after a weld. Second do a cut and etch of a weld or 2 done with this machine. I've seen too many pretty welds fail over the years to trust this process without those 2 things.

Ответить

smart and lasers can clean it afterwards

Ответить

레이저용접 사기인데?

Ответить

Photons and electrons are the same, one is travelling a different way to the other. So they can both do the same thing. Which is obvious

Ответить

Ой не зря он пластинку не перевернул! Но торец показал - там провару 2мм только. И чо с этим делать потом?

Ответить

Is this a real idiom?

Ответить

How much metal actually stays on the plate cause that's a while bunch of waste

Ответить

Which welding gun is better..?

Qilin, relfar, raytools..?

if you use filler to start the tig weld on the no filler one with the gap it works

Ответить

The wire melt faster than the size of the gap. I mean in the gap stay to long in liquid form the melted metal(wire). Probably a bit ticker wire or faster feed rate or even wider laser beam would doing amazing job. They using laser in car factory and everywhere nowdays, so the gap is not problem at all.

Ответить

❤👌👍

Ответить

Karbon Stil yada paslanmaz borularda kök atabilir mi bu makina

Ответить

Laser is garbage. Fusing is garbage unless it's an outside mitered corner of something non structural.. I don't see Laser working for anything but cosmetic decorative purposes

Ответить

I bought an intercooler that was Laser welded. Probably no material used, I immediately took it to work and dropped some dimes on it.. won't blow apart now..

Ответить

Great You solved my queries which many manufacturer could not solve but your demonstrate explain me. However, I still have some doubts about the laser welding equipment and it's usage Thanks a lot for such a beautiful demonstration.

Ответить

A bunch of incompetent and misinformed information on here !

Ответить

I want to see the root of the weld?

Ответить

How much for one of those Lazer welders? Would be pretty cool to have one. Almost like Mig welding seems like.

Ответить

Why are you embarrassed to show the reverse side of the weld? Is it for adults only?

Ответить

Woow..You solved a big doubt in my mind which I asked many manufacturers and suppliers but they couldn't demonstrate nor could they explain me. However, I still have some doubts about the welding joint quality, in terms of welding strength. But thn too this looks good for ligh applications. Thanks a lot for such a beautiful demonstration.

Ответить

나래이션?!? 헐

Ответить

Jajajaj el final del video

Ответить

Kamsamnida, addashi!

Great video, and my mind is made up. I am buying a laser welder.

Not with a wobblehead laser

Ответить

What size wire and feed rate are you using for the gap bridging? Thanks.

Ответить

Очень полезно, спасибо, я с такими зазорами уже намучился, буду пробовать по вашему методу😉👍

Ответить

Отлично

Ответить

Absolutely crazy-awesome!! Now, when will Harbor Freight push out a cheaper version; I don't have a spare $20K lying around...🤓

Ответить

The number of times I've told coworkers to not leave gaps when laser welding without wire because of the joint type and I start making holes from gaps and the ones that haven't used the machine just tell me to tweak the settings

Ответить

![[HBD I R عȵ] ► так красиво [HBD I R عȵ] ► так красиво](https://ruvideo.cc/img/upload/c0syS0FUdHpQVWY.jpg)