Комментарии:

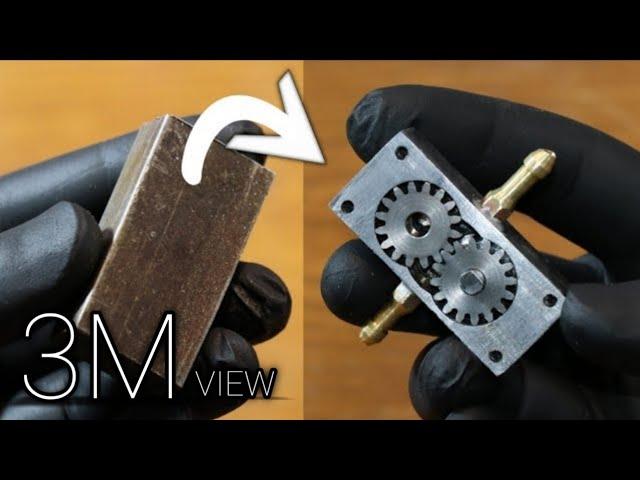

The gap between the gears and the walls of the pump is very large

Ответить

Do appreciative for creativity but not criticism

Improvements for that is other things

Please hindi

Ответить

very cool👍

Ответить

👍

Ответить

What a terrible video !!!… please… don’t do more like this.

Ответить

Сверлить под обойму подшипника... Паять валы... Теперь я видел все грани криворукости и ужаса металлообработки.

Ответить

you know if you put an electric motor on that, with a closed loop hydrolic..that s some thing for the

tool box... i like...good job...

Pra que todo esse trabalho, é mais fácil comprar uma bomba dessas ,super barato no Aliexpress

Ответить

I'd rather do body of bronze or brass, coz for this application it could be easier to turn chambers. Fine idea. Good lack.

Ответить

Сколько очков давит?

Ответить

I think your lathe tools and drills need sharpening

Ответить

Amazing, I run a lathe but I dont have smal stools as you, I would like to make one pump for me too

Ответить

Top show perfeito o trabalho 👏👏👏🤝👍💖🇧🇷🇧🇷🇨🇮

Ответить

This can be a awesome thing if only some companies mass produce hobby products like these. Fine surface qualities and tight tolerances can be achieved via hard sintered metal internal internals. It could build considerable amount of pressure. Rerspect to video, i was thinking some guy trying to build something fun with scrap but it turned out quite quality piece in the end. Check out the last seconds of the video, you can clearly see electric motor suffers and rpm decreases, this shows that internal leakage of the pump is quite low.

Ответить

add a 18v tool battery connector, and connect lights to it or a 1phase power outlet where you can connect yoru tools, and a short power line and holder for the cable so it can reach power anywhere in your shop. and a work light, usb charger etc, so you can charge your phone, battery speaker etc. and still have enough outlets for two tools. 2,5mm wide core so it has enough power to run 16a loads safely, and you can connect your welder, and angle grinder safely with out burning the cable.

Ответить

Распределитель надо

Ответить

WOW! THAT'S NICE!!😉

Ответить

I like it, very nice project!

Ответить

Amazing job... invest in some high quality lathe bits, they make life easy <3

Ответить

Nice metal works, but seems like it's a bit overkill. Printed nylon pump would be cheaper and almost same efficiency for low pressure like this.

Ответить

That is pretty cool. My one bit of advice if you want to make higher precision stuff is to know that threatds are not too accurate for locating the centre of holes. It is better to use dowel pins or some sort of expanding mandrill

Ответить

That was awesome 🙂

Ответить

I admire your desire and willingness to do this with what you have. BUT - One good grab of the drill while you are HAND HOLDING YOUR VICE and you are going to tear your hands up. This is a really bad idea. You should invest in a simple X/Y table for your drill press so you can securely hold your work AND POSITION IT FOR DRILLING - krazy gluing the gears to the plate and then eyeballing the undersized drill's center in the hole? Pretty mickey mouse. So is holding round parts in square jaws (use a V-Block) and putting flat stock in the vice without parallels under it. And your finish quality from lathe turning is .... weak. THis is partly because of your tool grinding. Get yourself some good indexable carbide insert tooling - NOT expensive - and you'll get much better results.

Ответить

hey man, nice work. what if you made another with larger diameter gears (lower relative gear ratio to the initial pump) and placing them in parallel, using a diverter valve to control flow/pressure to either, would you then be able to create a cvt: constantly variable transmission, capitalizing on the differential range between the ratios of the two pumps that power a common driveshaft?

i.e. as constant flow under pressure is diverted from the the larger diameter to the smaller, would not the common drive accerlerate (losing torque/gaining rpm)?

any and either way, thanks for sharing your efforts and ideas

peace

Bravo pour ce travail minutieux et précis. Quel plaisir de vous voir travailler. 👍

Ответить

Класный мини насос молодец.

Ответить

Bravo❤❤❤❤

Ответить

Great Lilliputian Project! Amazing workmaship.👍

Ответить

Nice

Ответить

Fantastic video and beautifully made!, liked and subscribed I would be interested to see it connected to a gauge to see how much pressure it can develop...

Ответить

: -)

Ответить

three obnoxious standard issue "like and subscribe" animations and the video is only a third of the way done. let your content stand on its own! usually i see one of those in the intro of a video this length, if any. i could see one at the start and at the end, even. but every minute? unnecessary.

Ответить

primitive and fail

Ответить

Very, very good!!. Thnak you for share it!!

Ответить

Excellent video ! 👍

Ответить

Слишком много лишних действий. Подшипники качения в таких насосах не нужны.

Ответить

Well its a cute project and a learning experience.

I would like to see the psi Guage results.

I always wanted a 2-bricks in a lunch-box pusher contraption. Very useful for pushing 2-bricks in a lunch-boxes.

Ответить

Өте керемет кішкентай май жүргізетін насос жасадын жақсы

Ответить

Wow very good job my friend 😍❤️❤️🎉

Ответить

a Vernier caliper to use as a gouger and shortcut scribbler.... LOL

Ответить

BEAUTIFULL, Magnifique! THx for inspiring me; merci, ça m'inspire.

Ответить

Kudos to you. Couldn't slip bearings be good enough for those cogwheels? Did you test how much pressure it can generate with that (drill) motor?

Ответить

What do you intend to lubricate with this little cutie?

Ответить

Good

Ответить

Шестеренный насос сделал и чЁ?

Ответить