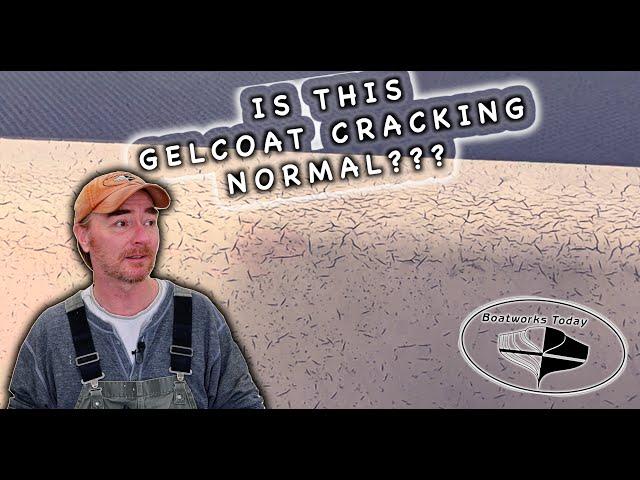

HOW DO I FIX ALL THESE GELCOAT CRACKS FOR PAINTING??

Комментарии:

I’ve always have it a light sand, high build primer, knock it back down and roll.

Ответить

where are you from?

Ответить

I stumbled on this one a bit late. Andy may have this one a bit wrong. Many race boats are full of balsa core, J boats in particular. They are a patchwork of balsa end grain squares. Newer boats switched to no wood core. It was the biggest advertising item as manufacturers switched from wood to better (more expensive) core, transom, stringer materials. I’d take a fully synthetic core construction any day.

Ответить

I wish you could write up the steps as you are telling it! Learning by listening only is very difficult, especially for people having issues or like me, as a French speaker haha! Thanks

Ответить

Thanks! Really nice explanation of the problem.

Ответить

Hey Andy great content its very helpful. I have a 26 ft 1967 Columbia sailboat. The boat is in good shape structurally, but the crazing and cracks in the gelcoat that you explained in this video are happening on every square inch of the hull and deck of my boat. Is there a way to fix this apart putting a new layer of fiberglass over everything? Thanks

Ответить

Why didn’t I find your channel sooner?!? Just in time though… I’m about to paint my dad’s old wayfarer, she had thermal crazing and gel coat cracking similar to the feature in this video. I took a 80 grit flap wheel on the grinder to it and got rid. Layered up with x2 gsm and poly resin and filler to fair it out, with the intention of gel coating to finish. I got distracted by a cheap purchase of a laser dinghy that had a crappy deck, which I sorted out and gel coated… never again will I try that 😂 wow.. it worked but it was stressful.

So, thanks for sharing your knowledge.

Hi

If I apply multiple non-wax gelcoats then apply a final wax gelcoat, would it cure?

Thanks

Unwell or not this is a wonderful instructional video.Thank you 🙏

Ответить

If you simply clean with bleach it will clear up much of the unsightly dirt and you won’t see the small cracks.

Ответить

If u were to use waxed gelcoat over a layer of glass would u still use primer before paint?

Ответить

Всё по делу , очень интересно слушать!) Спасибо!

Ответить

awesome! I know chuck

Ответить

Where you located. Thanks

Ответить

I love your videos but I have to disagree with you on the paint over gelcoat part. Only because gelcoat is a lot easier to fix in the long run and will last longer. And if thinned properly using the right materials you can spray gelcoat damn near like paint. To where you just have to hit it with 1000 grit then buff, polish and wax it. Which if you aren’t a painter you’re gonna run it or have orange peel so you’re gonna have to do that process anyways. Just my opinion for doing this work for 17 years now and doing full hull gelcoat resprays every day for the last 2 years including metal flake, pearls and chameleon additives in the gelcoat.

Ответить

Hello Andy I don't know if my issue is video worthy! But what are you thoughts on liquid transom vs plywood?

Ответить

The gel coat with wax additive is often referred to as ‘flowcoat’ isn’t it?

Ответить

Please make a video on this... I have a Lagoon 440 with tons of areas like this....!!!

Ответить

This is the perfect video! The entire top side of my 88 Wellcraft has this cracking .

Ответить

Please don’t do it the way he said, degrease the surface and wash, sand with p120, rolle on 3 to 4 coats of and epoxy primer like 545 with no thinners, apply by foam roller, this will seal the crack’s, bigger ones, use some filler, sand all the surface p120/p220, apply 3 more coats by spray if posssible, sand with p320/400 and apply 3 @awlgrip gline topcoat roll and tipping and you will be fine for 10 year’s.

Ответить

I used wet edge one part paint with soft sand it looks great, but it tends to take a long time to dry. It may cost more for the two part, but it save time . If I had to do it again I would use two part paint.

Ответить

Great content. I just love this channel. Much love from Maryland❤❤❤.

Ответить

Could you please link to a video you must have about how much of the one part vs. two part considerations applies to below the waterline? We need an education for our 1978 C&C 34. TIA. Burke

Ответить

Are you talking about putting a new layer of fiberglass over the entire top of the boat that's going to be repainted?

Ответить

Great video as usual, thanks. I think maybe you should mention that you can't use 2 pack paint on top of 1 pack, so if the existing non slip is one pack you have to stick with that. Fair winds.

Ответить

I think new gelcoat is the best. If your going to be sanding anyway to paint fill the just do gel coat.

Ответить

I had to deal with exactly the same cracks! Sanding down the gelcoat and laying up new csm and finishing it is a lot of work.. I took a different approach which has worked well! Pressure wash/clean the surface thoroughly first. Chips might come flying off; these spots need to be filled obviously. Sand the surface and paint with a well thinned epoxy primer. Smoothen and prime again and finish with a 2comp paint system. So far this has lasted for 4 years and still looks great! Good luck whichever method you choose!

Ответить

Buy once,

cry once !

2k, all the way .

Great video as always.

Just a small nuance if I may -- what product to use to finish off the kind of gelcoat cracking shown here depends on whether the surface is going to be sitting continually (or long term) in water. I am thinking here specifically about boat bottoms,

Gelcoat can withstand long term water immersion. Many paints cannot, whether they are one part polyurethene or two part catalyst-type paints (antifouling paint being the exception, of course).

The point being....READ THE INSTRUCTIONS for the product you intend to use.

I have used one part paints for the bottoms of dinghies with no problems, but those boats are always pulled out of the water after use. Many two part paints warn about long term immersion (even multiple day immersion).

Thanks Andy. I’ve been following you for years, and I’m glad to see you going, your work is deeply appreciated

Ответить

On a racing sailboat use KiwiGrip or similar. Better for traction and sails on deck. If you do Sand, your crew will hate you.

Ответить

My '68 Mark Twain is covered in that. Been looking for an answer to how to deal with this for years. I was hoping multiple coats of high build primer would cover that up. Not really looking forward to covering the whole boat in another skin of chopped strand.

Ответить

I have been wondering about using vacuum bagging techniques to fill gel coat cracks before sanding and painting.

My thought is based on the method used for impregnating electric motor coils. The wound wire coil is placed in a sealed tank and the air evacuated which creates a vacuum INSIDE a the wire coil. The tank is then flooded with resin, then the vacuum is released on the tank. The vacuum inside the coil sucks in resin completely encapsulating the individual wires inside the coil.

It seems to me the same process could be used on a crazed gel coat deck with so like the following procedure:

1. Clean the surface well.

2. Degrease the surface and cracks with a solvent (I acknowledge the contamination inside cracks may be difficult to remove)

3. Vacuum bag the surface. Use a porous distribution fabric to permit a good vacuum under all areas of the bagged area. Connect fill tubes to the vacuum bag system to the resin container

4. Pull a vacuum on the surface

5. Break the vacuum with resin and observe the resin flow into the crack depth.

6. Sand the filled surface and paint as usual.

I’m hoping this method would fill the cracks and surface roughness sufficiently to support sanding to a smooth surface; avoiding the need to add Matt or chase

-and-fill each crack.

This may be a novel method looking for someone with the vacuum equipment to experiment.

Cheers.

Tom Fenn

Yorktown, VA

Hi there, I hope your shoulder is on the mend and thanks for your very informative videos. Please keep them coming.

With regard to Nonslip finishes, I have always worried about having to sand the grit particles by sanding when repairs have to be made. allot of effort.

I have been using sugar crystals to provide the Nonskid texture. Firstly a coat of two-pot then broadcast the sugar while still wet , once hardened another layer of two-pot as top coat. Once thoroughly dried a light sand to knock of the sharp edges of sugar then a thorough wash to get rid of the sugar. This leaves a crater like surface that gives good traction, like little suckers, with no foreign material in the finished surface. Very cheap, easy to repair, and won't wear out your pants. Give it a try I would like to hear your comments....

nice 20 thousand fix for a 10 thousand boat

Ответить

When I looked at the crazing, I thought that you would be thinking that the layup wasn't quite thick enough because it seemed to me that the topsides were bending and breaking the bond at the corners as a result. The flat areas didn't seem to have the same amount of crazing. Will adding CSM actually do much to beef it up? I'll defer to your experience and expertise but I did see this in a restoration I did a few years ago and I beefed up those areas and saw no crazing return.

Ответить

Sanding, fiberglassing, fairing, more sanding, then painting. This is not going to be a weekend project.

Ответить

Love your videos.

I don't have a boat, but I am helping my son restore an older car with a fiber glass body. (A 1971 Saab Sonett.) There is not much instruction out there for cars. I just really find your approach helpful and clear. Thanks.

Great explanation, Andy. I used Total Tread on my home built skiff. I can’t remember if I put on 2 or 3 coats but after a year of light use it seems to be loosing grip already. I also used Wet edge for the hull and with the humidity here in Florida and we were getting a lot of rain at the time, I would have to wait 3 or 4 days for the paint to cure enough to sand.The paint came out great, but if you’re in a humid area it may take a while to build up coats. I rolled it on very thin as the instructions said.

Ответить

Could you link the products recommended to handle with cracks as you described in the video please?

Ответить

My 32 year old boat is covered with similar hairline crazing but longer than shown here and is only on all top surfaces that were exposed to sunlight. The sides of the hull have zero crazing. I've been wondering whether to re-gelcoat or paint. I think paint will cover the crazing and be less work.

Ответить

Good information Andy, thank you.

Ответить

Great info/video - thanks! I was always told that when gelcoat is applied too thickly that it eventually crazes and cracks. Is that true?

Ответить

Thanks Andy. Great information here that I will definitely be coming back to on my project!

Ответить

That's not the typical reason for crazing. Crazing is normally caused by incorrectly catalyzed gel coat that is applied too thick.

A dry layer of glass against the gel coat doesn't help, but it's not normally the cause. That's a different failure mode and looks different.

When younger I spent time racing cars. Paint at 2 feet is different then 20 feet. Worry more about what you are happy with than what your posh friends say. Have a great day

Ответить

That looks like my bathroom ceiling :-) Luckily. it's easier to fix that cracked gelcoat!

Ответить

![Toxic - DMP56 (official music video) [shot by ron21hoops] Toxic - DMP56 (official music video) [shot by ron21hoops]](https://ruvideo.cc/img/upload/ZzVYaUd3LW1jeFk.jpg)